Lang Tool Co. has been involved in several projects that used ISS/ISCO soil mixing as the remedy. ISS/ISCO is a soil mixing procedure that uses Portland cement to activate sodium persulfate and is applied in one pass. The process uses the persulfate to destroy various contaminates such as PAHs and TCE and has the added advantage of decreasing the hydraulic conductivity of the soil. The treated soil is strong enough to allow redevelopment construction on the site to begin immediately after ISS/ISCO is completed.

Lang Tool Co. has performed many ISCO & ISCR soil mixing projects using a variety of reagents. They were successful in that the sites met the cleanup criteria but they all shared one feature. When ISCO was finished the sites where so wet that they were unusable for a long period of time.

This photo was taken on a project that we did with Environmental Field Services in Ashippun WI using PeroxyChem’s Daramend product for the reagent. Completion of the project was delayed by months due to the difficulty in backfilling. Note that there was a layer of clean overburden that had to be stockpiled and later returned. Stock piling and returning soil is commonly referred to as double handling. As will be shown later in this presentation, stockpiling is eliminated using the ISS/ISCO process.

This photo was taken on a project completed with ISOTEC in Conway NH using MFR. As is often the case with chlorinated solvent contamination, there were several feet of clean soil above the contamination that had to be removed before the ISCO process. After the completion of soil mixing Lang Tool Co. waited for two days for the last round of test results to come in before demobilizing. The test results came back showing that the ISCO process had met the cleanup criteria. However, the contractor that was to perform the backfilling had a difficult time and in the end the treatment area had to be stabilized before any backfilling could be accomplished. ISS/ISCO is applied in one pass reducing the overall cost of the project.

The photos above were taken on a project we did with Fehr Graham at the Danfoss factory in Ames Iowa. As you can see the ISCO treatment resulted in the site being very wet when ISCO was completed. The operator of the sunken piece of equipment found out how soft the site was. The engineer sent me this photo 3 months after we completed the soil mixing. It is lucky that the operator made it out of the machine as he had to exit through the front. All three of these projects met the cleanup criteria but all three sites were not in a usable condition for a long time after ISCO was performed. ISS/ISCO solves this problem. An example is the Kent Cleaners project that Lang Tool Co. completed in Lansing Michigan.

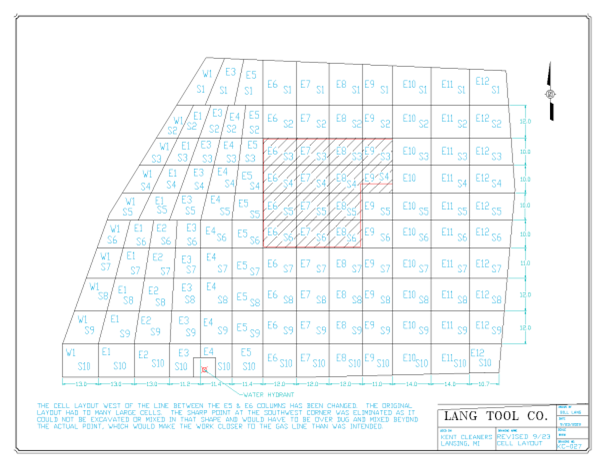

This is the treatment cell layout and designation for the 12,400 cubic yard ISS/ISCO project. The site was a former large scale dry cleaning facility. The contaminated area was the entire property that is bordered on two sides by streets and residential property on the other two sides. The reagents were Klozur persulfate activated with Portland cement and a small amount of NaOH.

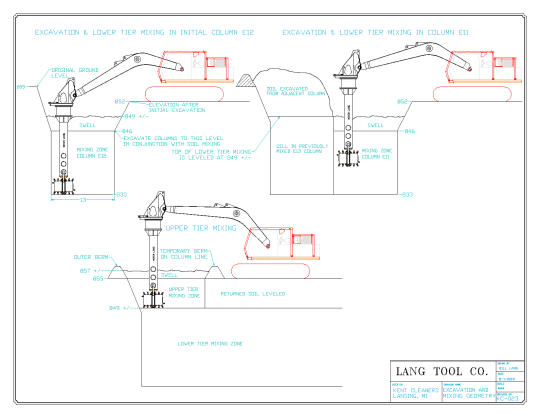

Initially approximately 3 feet of low level contaminated soil was excavated and hauled off. The highly contaminated soil extended 19’ below the initial excavation requiring that the ISS/ISCO work be performed in two lifts. It was anticipated that swell generated by ISS/ISCO would increase the elevation by around 25%, which proved to be fairly accurate. The E12 column, which is on the extreme east end of the site, was excavated to 846’ as shown on the top left. This soil was leveled over the eastern half of the site. ISS/ISCO began in the E12 column, which took about 1 ½ days. On the morning of the 2nd day soil excavated from the E11 column was deposited on the previously stabilized E12 column as shown at the top right. Soil mixing and excavation proceeded in this manner from east to west until the E7 column lower level was completed. At that point ISS/ISCO of the upper tier commenced in column E12.

Initially approximately 3 feet of low level contaminated soil was excavated and hauled off. The highly contaminated soil extended 19’ below the initial excavation requiring that the ISS/ISCO work be performed in two lifts. It was anticipated that swell generated by ISS/ISCO would increase the elevation by around 25%, which proved to be fairly accurate. The E12 column, which is on the extreme east end of the site, was excavated to 846’ as shown on the top left. This soil was leveled over the eastern half of the site. ISS/ISCO began in the E12 column, which took about 1 ½ days. On the morning of the 2nd day soil excavated from the E11 column was deposited on the previously stabilized E12 column as shown at the top right. Soil mixing and excavation proceeded in this manner from east to west until the E7 column lower level was completed. At that point ISS/ISCO of the upper tier commenced in column E12.

In the photo above left the Dual Axis Blender is mixing in the E11 column. The excavator is digging the E10 column to 846 and depositing the soil on the northern end of the E11 column that was treated the day before. The stabilized soil in the E11 column can be seen at the bottom left of the photo. ISS/ISCO eliminates a lot of double handling. In the photo above right the Dual Axis blender is mixing in the E10 column that was being excavated in the picture at left. The excavated upper level soil has been leveled over the E12 & E11 columns on the left side of the picture. Note that there was no stockpiling of excavated soil. This is true on projects such as this that require an upper level of treatment and on projects that have a clean upper layer that doesn’t require ISS/ISCO. ISS/ISCO using the two tier approach allows smaller more efficiently mobilized equipment to perform work that previously required larger equipment thus substantially reducing mobilization costs.

ISS/ISCO was completed late on a Thursday afternoon. Friday the equipment was cleaned up and some of it demobilized. Monday the rest of the ISS/ISCO equipment was demobilized. Tuesday the bulldozer leveled the site. At noon Tuesday the site was usable.

ISS/ISCO was completed late on a Thursday afternoon. Friday the equipment was cleaned up and some of it demobilized. Monday the rest of the ISS/ISCO equipment was demobilized. Tuesday the bulldozer leveled the site. At noon Tuesday the site was usable.

The project involved:

- 12,353 cubic yards of ISS/ISCO

- 440,800 lb. of Klozur persulfate

- 15,080 lb. of NaOH

- 816 tons of Portland cement

- 28 working days of soil mixing

- 1 day initial setup

- 2 days cleanup & demobilize

- ½ day to level the site0

This photo was taken on December 10th, about a month after Lang Tool Co. left the site. A grading contractor was hired to import topsoil and perform finish grading. The site security fence was removed. The site is now ready for development. Note that the pozzolanic reaction was still ongoing as the snow is melted from the surface of the site. This site could not have been treated with ISCO alone as the resulting mud mess would not have been acceptable in a residential neighborhood. The estimates for dig and haul were over $2 million more than the cost of ISS/ISCO.