SOIL MIXING EQUIPMENT

Dual Axis Blender

Lang Tool Co. has developed most of the soil mixing equipment that it employs in-house. The LTC designed and manufactured Dual Axis Blender is unique in that the main drill stem turns on a vertical axis while the drums on the lower horizontal axis counter-rotate. Powered by a 490 hp engine, the DAB produces a violent mixing action. The reagent plumbing outlet is in the middle of the mixing action. The DAB has been used successfully on a multitude of projects including those involving an ISCO process in hard glacial till clay. Equipped with GPS, the Dual Axis Blender knows where it’s going and where it’s been. Contact Lang Tool Company for your soil mixing equipment needs.

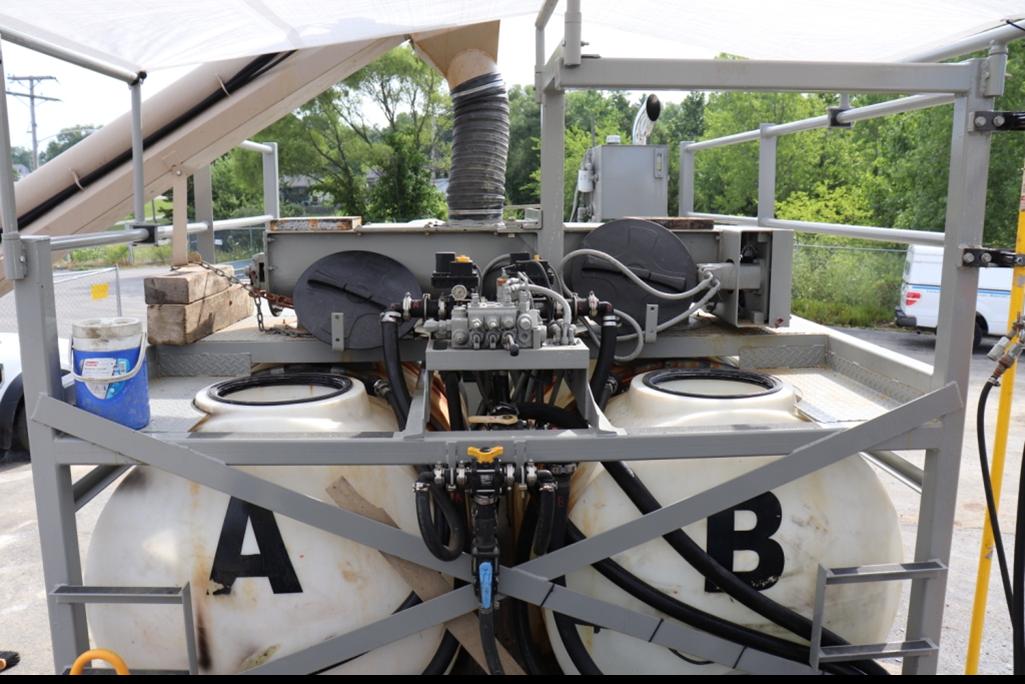

ISCO Plant

The Lang Tool Co. ISCO Plant consists of a dry bin with scales, a mix truck with two 750 gallon tanks, two platform scales and a diaphragm pump. The dry bin is loaded with a service truck equipped with a crane. Drums or totes of liquid reagent are placed on the platform scales with a forklift. The liquid is pumped off the scales with the diaphragm pump. The plant operator enters the gallons of water, the weight of the dry reagent and the weight of the liquid reagent into the onboard computer. When the entered quantities of each reagent component is reached the delivery shuts down to prevent over filling, leaving the plant operator free to watch the delivery. While “A” tank is being filled, reagent is being pumped from “B” tank and vice versa. This allows soil mixing to proceed without stopping. The plant operator can control the rate of delivery to the blender to match the rate of mixing progress. The delivery shuts off when the entered quantity is reached.

ISS Plant

The Lang Tool Co. ISS Plant consists of a mix truck with a computerized scale system, a piston grout pump and either one or two 35 ton silos with scales, depending on job specific conditions. The plant produces slurry on a continuous basis. The plant operator enters the total weight of cement to be delivered to a mixing cell and sets the rate of delivery, in lbs/minute, and the water ratio. The rate of delivery can be adjusted at any time to match the mixing progress of the blender. The water ratio can be changed as well if site conditions vary. When the entered quantity of cement is reached the system shuts off the delivery, which prevents any inadvertent overdosing. Lang Tool Co. frequently averages over 125 tons of cement a day on ISS projects.

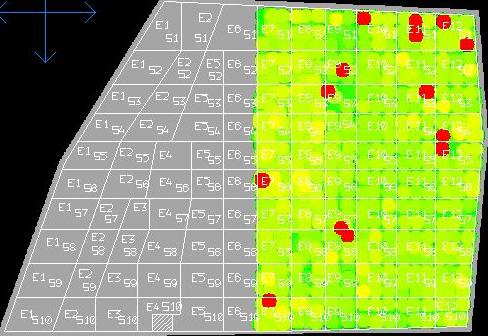

GPS

The chart above was downloaded from the DAB computer. It shows that the treatment area was mixed to the specified horizontal and vertical coordinates. Lang Tool Co. has a GPS rover on site at all times as well.

When the horizontal and vertical limits of a soil mixing project are established, Lang Tool Co. prepares a CAD drawing of the cell layout for the project and a surface drawing that conforms to the bottom mixing elevation or target. The bottom surface can vary if the project specifications call for different target elevations on various parts of the mixing area. LTC used these files to create a GPS program for the project.

When the GPS program is loaded into the Dual Axis Blender computer the operator sees the cell layout, the cell designation, the machine and the blender head. “DIST” is the distance to the bottom mixing elevation or the target. The cross-sectional view on the right of the GPS screen shows the mixing progress toward the target. This screen is broadcast to the reagent plant operator so he has real-time information on the mixing progress, which allows him to match the rate of reagent delivery to the mixing rate of the blender. The screen in the photo is the screen on one of the reagent plants. The screen turns green when the blender is between 0.5’ above the target and the target. The screen turns yellow when mixing is between the target and 0.5’ below the target. When mixing is deeper than 0.5’ below the target, the screen turns red.

220-LTC

The 220-LTC tool carrier equipped with an LTC Deep Digger blender is well suited for shallower ISS or ISCO soil mixing projects.

Specifications:

- Equipped with GPS

- 400 horsepower

- 130 gpm @ 5,500 psi attachment

- Hydraulic pump

- 65,000 lb operating weight

- Deep Digger Blender specifications:

- Torque – 26,000 lb/ft

- Rotational Speed – 0-80 rpm

- Drum Width – 28”

- Drum Diameter at Bit Tips – 54”

- Weight – 7,000 lb

- Bits – Various flat shovel and conical carbide arrangements

OFFICE LINE

1-989-435-9864

GET IN TOUCH

WORKING HOURS (EST TIME ZONE)

7:00am – 5:00pm

OFFICE LINE

1-989-435-9864

GET IN TOUCH

WORKING HOURS (EST TIME ZONE)