Project Description

Former Dana Site ISS/ISCO Project

Columbia City, Indiana

Project Details

DATE OF COMPLETION

September 2019 (14 working days soil mixing)

PRIME CONTRACTOR & ENGINEER

PROJECT TYPE

ISS/ISCO

PROJECT DESCRIPTION

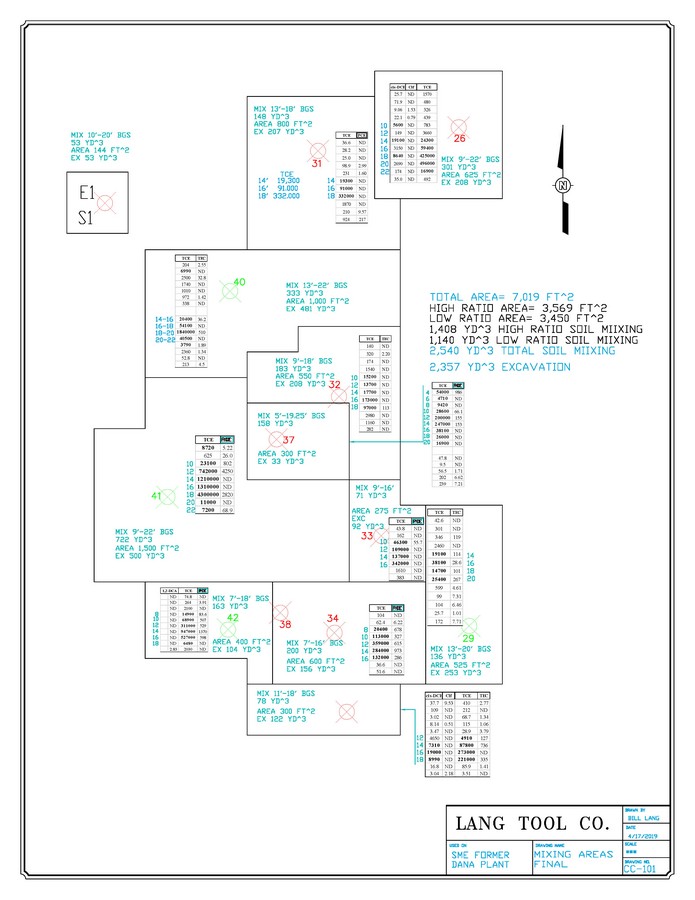

Perform ISS/ISCO on 2,550 cubic yards of soil contaminated with chlorinated solvents and treat 1,605 cubic yards of soil with Daramend

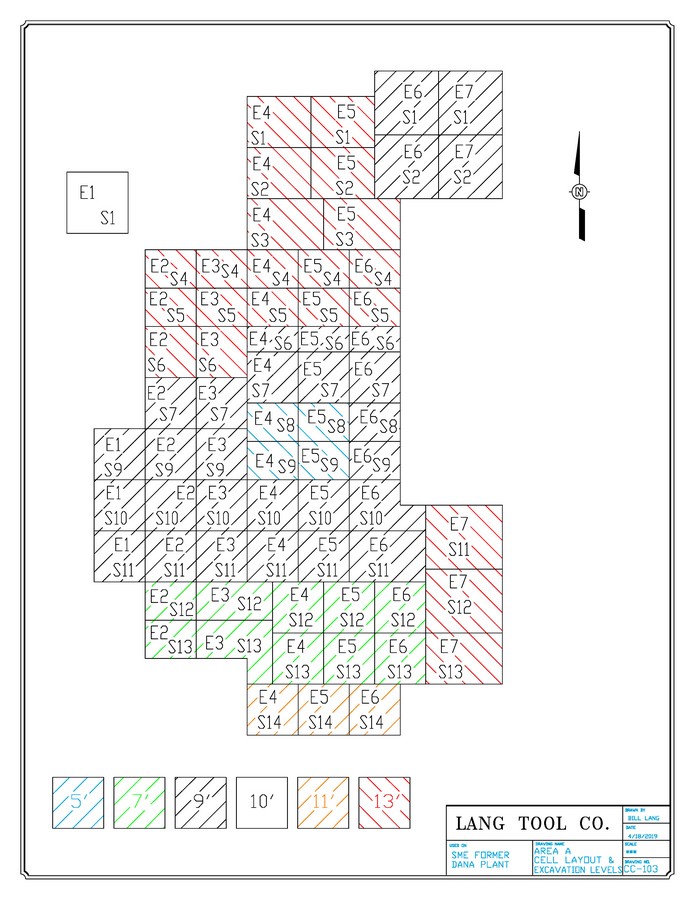

As on many sites contaminated with chlorinated solvents, the Dana site had clean overburden at varying depths overlaying the contaminated layer. A cell layout and designation was worked out. GPS on both the blender and the excavator is essential to efficiently perform ISS/ISCO on sites such as this.

Using ISS/ISCO eliminates the double handling associated with stockpiling and returning the excavated overburden. The work began with the excavation of the E2 column. The overburden was spread over the treatment area to the east of the E2 column. When mixing was completed on the E2 column, the E3 and E1 columns were excavated and the soil was placed on the E2 column. Excavation and mixing continued in this manner until the ISS/ISCO was completed.

Shown to the left is the LTC ISCO Reagent Plant; a mixing truck with two 750 gallon mixing tanks. Drums of NaOH are placed on the truck platform scales. A diaphragm pump is used to transfer the NaOH to the mixing tanks. The dry bin has a computerized scale system that conveys persulfate to the mixing tanks. The crane (pictured left) on the service truck is used to load the bulk bags of persulfate into the bin. The ISCO Reagent Plant pumps the mixture of water, Klozur and NaOH to the LTC ISS Reagent Plant where it is mixed with cement and pumped to the Dual Axis Blender. The photo above is of both plants set up on the project. In the photo (top left) the excavator is removing the clean overburden ahead of the ISS/ISCO application.